Technological advancement makes it possible to mass produce tiny spectrometers using standard chip-making processes

01/30/2019 / By Edsel Cook

MIT researchers came up with a novel way to produce smaller and cheaper spectrometers – by leveraging existing techniques to manufacture computer chips.

A spectrometer is an instrument that can tell the difference between various wavelengths of light. It can find out the chemical composition of an object based on the light it reflects.

The typical spectrometer is a big and bulky device with an appropriate big price tag. They are restricted to the large laboratories, observatories, and universities that can afford to buy and operate them. And even those facilities can usually only afford a couple of units at most.

The method described by the MIT researchers in the science journal Nature Communications can produce highly compact spectrometers that retain the accuracy and power of the bigger units. The devices will also be cheap enough to be built in large numbers using existing chip production lines.

Lead researcher Juejun Hu said that smaller and less expensive spectrometers would be welcomed by organizations that normally would not be able to afford one. The devices could also be used in roles that were once unavailable due to cost, space, and weight constraints. (Related: Small, flexible sensor being developed to detect specific chemicals or viruses.)

New chip-based spectrometer saves space by switching to optical switches

This is not the first attempt at a small spectrometer built from chips. Miniaturized spectrometers do exist. But they perform much more poorly than their bigger equivalents.

Spectrometers work by spreading out light based on wavelengths. Most of them use an optical approach, while some rely on the math-based Fourier transform method.

To get the most out of either method, a spectrometer needs long optical paths that can be tuned according to any requirements. And only large devices can fit the large movable mirrors that can scan the light from distant stars and complex materials with sufficient accuracy.

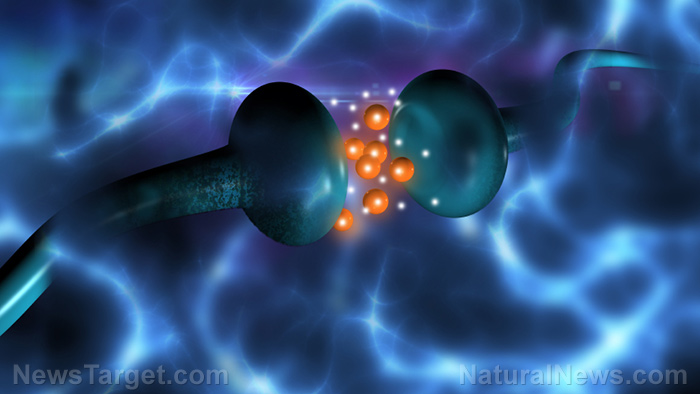

The MIT researchers looked for an alternative means of spreading light. Their system uses electronic optical switches that can send light beams through multiple optical pathways.

Each pathway is of a different length in power-of-two increments. Several lengths can be combined in various ways to create an exponentially increasing number of discrete lengths. The more on-chip optical switches in a unit, the bigger its spectral resolution gets.

By replacing the movable mirrors with optical switches, a spectrometer can be shrunk down to a much smaller size without compromising the performance. It can also be built using current computer chip production lines. Last but not least, it will be much sturdier than its bigger counterparts thanks to its fewer moving parts.

The next big thing in spectrometers is making them smaller

The MIT researchers partnered with a semiconductor manufacturing company to produce a chip-based spectrometer with six sequential optical switches. The prototype can scan 64 spectral channels and has the processing power to handle itself and go through its output. Adding four more optical switches increases the resolution to a whopping 1,024 spectral channels.

The device is a plug-and-play unit. Optical channels can be added and removed with ease. It can also be integrated with optical networks.

If only a small number of channels are available, the spectral readings can still be reconstructed through machine-learning methods. Testing confirmed the accuracy of this means of recovering data.

The new chip-based spectrometer can be used in sensor systems, materials analyzers, medical imaging systems, and optical network monitoring systems. They could also be used to keep track of industrial processes and the environment effects of those same industries in real time.

Visit FutureScienceNews.com for more articles on the latest scientific instruments.

Sources include:

Tagged Under: breakthrough, computer chips, future science, future tech, innovation, inventions, lab instruments, machine learning, new technology, optical materials, optical switches, science and technology